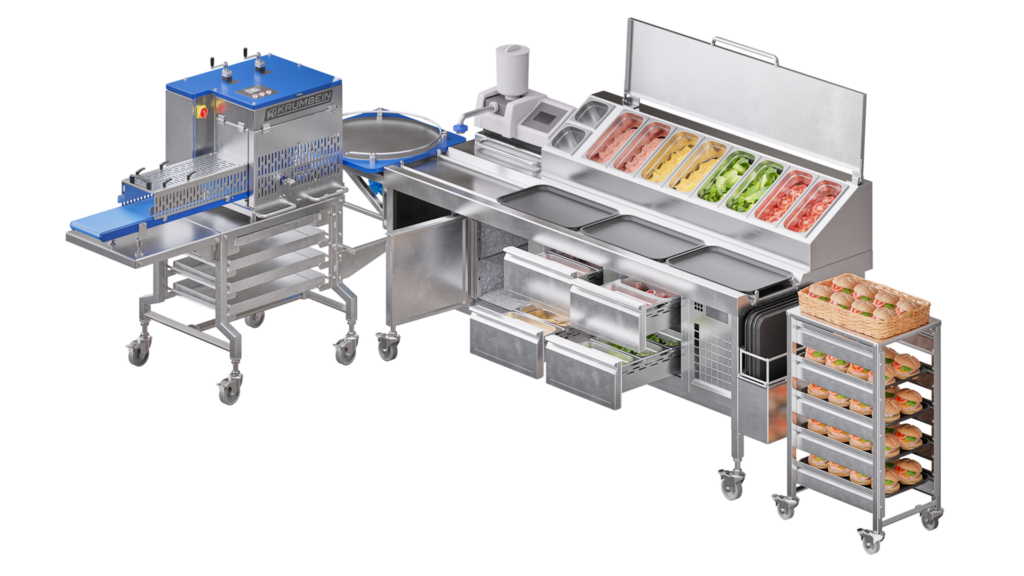

FILIsnack cut 'n' cool

Compact and time-saving solution for in-store snack production

All-in-one solution for in-store snack production

The new FILIsnack cut ‘n’ cool combines all important process steps for the production of sandwich snacks in a minimum of space and was developed for one-person operation in stores or central production. Cutting of different bakery products, topping of the products with fresh and cooled raw materials as well as direct preparation for display in the sales counter: The FILIsnack is designed for the further processing of rolls, baguettes, bagels, small flat breads etc. in the branch or in a small space.

- All-in-one solution that combines all important snack production steps

- fast production of ready-to-sell snacks on trays

- One-person operation

- integrated raw material cooling

- can be positioned as line or over corner

- powerful cutting machine

- possible integration of compact depositors

- hygienic design

FILIsnack cut 'n' cool: Benefits at a glance

All-in-one

integrated cutting technology

Integrated cooling

Adaptable solution

The FILIsnack is designed so that it can be positioned in a line or as a corner solution, depending on spatial conditions

Are you interested in our in-store solution?

We’re happy to talk to you more in-depth.

Stefan Wich Heiter

Sales Department