Snackline - SnackFlexLine

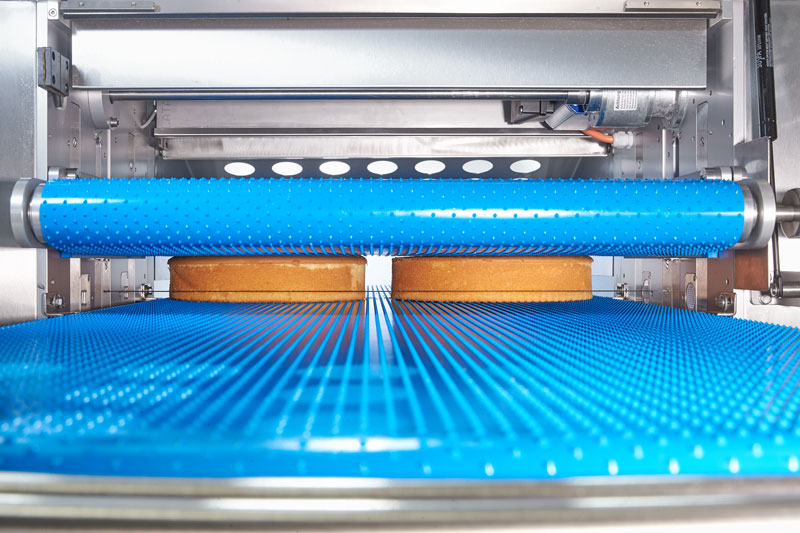

The snack business at the bakery is in demand as never before. With our SnackFlexLine production line, we supply a modular system that can be expanded and adapted to your production needs at any time. With the snack line, you can produce sandwiches, baguettes, bagels, salads, etc. quickly, economically, and extremely hygienically.

Flexible Produktionslinie - SnackFlexLine

With our modular production line, you can (partially) automate important production tasks in your snack business. All machines from our range can be combined to form a line, and accessories and additional machines can be used to increase the variety of products. A clever design also relieves the personnel on the line with ergonomic workstations and easy cleaning. Decide for yourself what degree of automation your production line should have – we will be happy to help you.

SnackFlexLine: Benefits at a glance

Modular system

Everything under control

Digital & modern

Clean solution

Numerous accessories

Touch-Display

KRUMBEIN - Your specialist for snack lines in bakery and industry

At KRUMBEIN you get everything from a single source – thanks to the well thought-out overall concept of the SnackFlexLine snack line, many possible combinations of our machines are conceivable. Based on our experience, we have summarized the before, during and after:

Before:

- Large selection of cutting solutions – perfectly matched to the respective requirement

- Horizontal cutting machines in various designs

- Vertical cutting machines with automatic transfer of the products with the cut surfaces facing upwards

- Buttering system for the effective application of butter, remoulade, creams, mayonnaise, sandwich spread, dips, sauces and much more, depending on requirements

During:

- Conveyor and document belt as a basis in different lengths and working widths

- Extension modules selectable: optimized storage systems for GastroNorm(GN) containers / Euronorm, worktops as work surface for hanging in, special storage systems for dosing systems, etc.

- Ideal combination with piston dosing system

After:

- cutting machines for dividing the finished products

- large selection of work tables for manual cutting or packing

- interface to well-known manufacturers of merchandise management systems, so that this process can be optimally integrated into the overall concept

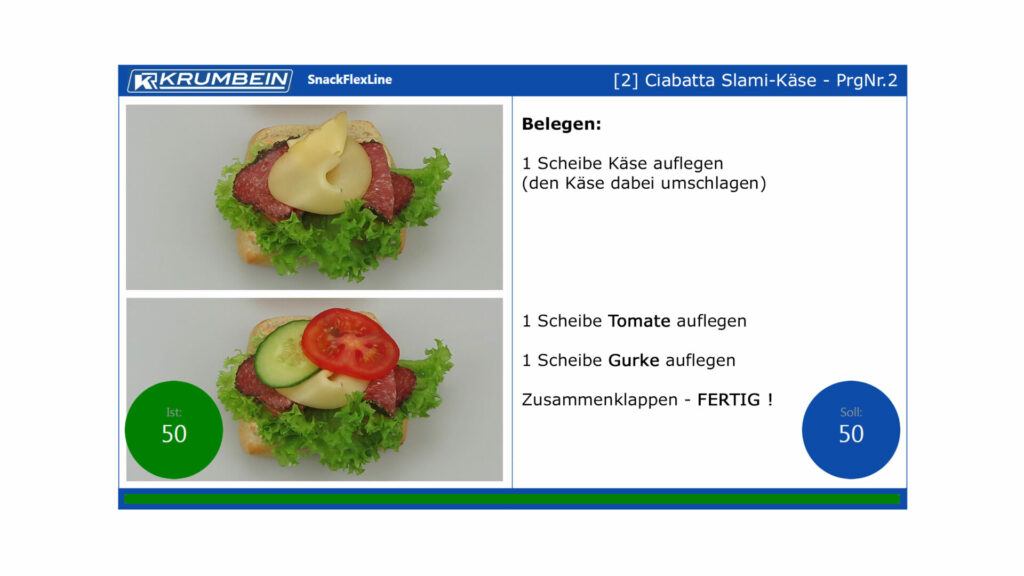

Recipe visualization: see what needs to be done

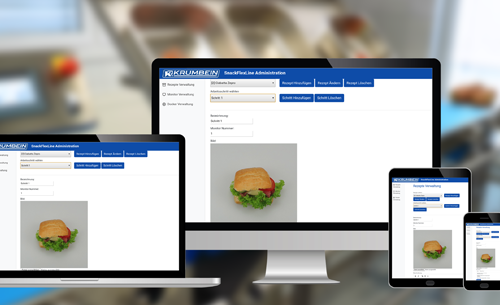

In combination with touchscreen control, a recipe visualization is available on the SnackFlexLine, which clearly conveys the most important information in words and pictures. Simply create photos of the individual work steps, add recipe information, send to the system – done!

Visualized covering instructions for each step:

- Freely positionable monitors, which are networked with the machine control, visualize the digital receipt instructions for the individual workstations

- Creation of recipes and process information, platform-independent on a wide variety of end devices (smartphone/tablet/notebook/PC)

- No need for long training periods: the personnel at the plant know exactly what to do – Increase in product quality

- Visualization of the production specifications – input of the target number of pieces & automatic recording and display of the actual number of pieces

- Any number of monitors can be connected to the carrier system on the line – Each monitor “logs on” independently

- If required, the recipe visualization can also be integrated into the customer network, which enables the transfer and evaluation of production statistics

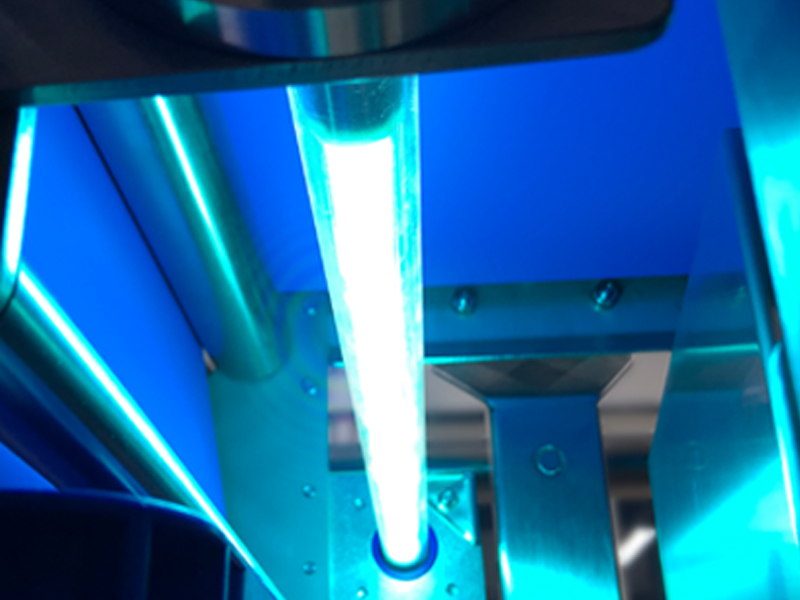

Highest hygiene standards thanks to UVC disinfection

For germ-free conveyor belts, KRUMBEIN relies on innovative UVC high-performance disinfection modules. These avoid cross-contamination and permanently reduce the total germ count. This extends the cleaning intervals between production shifts.

Compared to conventional UVC lamps, the special UVC lamps used have an UVC output that is approx. 4-times higher while having the same overall construction length. In addition, the unique Flat-Lamp-Technology emits more than 50% of the generated UVC power directly onto the surface, resulting in an enormously high efficiency.

The disinfection modules can be easily selected as an option when putting together your personal SnackFlexLine.

Fitting machines for your production line

VSM-120 – Vertical Cutting Machine

Do you want to automate your snack production?

Even your existing KRUMBEIN production line can also be optimally expanded with machines or accessories. Together, we will find the perfect solution for you.

Daniel Pfohl

Key Account Manager